TRUMP TARIFFS: How one car piece crosses Canada, U.S., Mexico borders 7 times

Scrap from Linamar Corp. crosses Canada, U.S., Mexico borders 7 times until it becomes an automatic transmission that powers a vehicle.

Article content

AUTO PARTS ODYSSEY

A transmission module, through seven steps, starts life in Ontario as scrap metal and goes back and forth across the border seven times. This is a summary of that journey:

Step One: Linamar, an auto parts maker in Guelph, has scrap metal on site and it sends that scrap to a smelter in Pennsylvania.

Step Two: Steel from that smelter and others is then sent to an Ohio company to make a part called a hub.

Step Three: The hub is then sent back to Linamar in Guelph where that hub is assembled into another part, a clutch plate for example, to be used in transmission assembly.

Four: Guelph receives from another supplier in Illinois parts also used in this assembly process. Linamar’s Ontario factory also imports aluminum housings from its foundry in Mexico’s Coahuila state. It assembles all these parts into a module.

Five: Linamar sends its parts to a plant in the midwestern U.S. where they are part of the assembly of transmissions. (This is F on the map)

Six: Transmissions are sent from the Midwest plant to an Ontario vehicle assembly plant (not Linamar) where they are put in vehicles.

Seven: Those vehicles return to the U.S. some stay in Canada of course, for sale on dealer lots.

Source: Linamar, auto parts maker in Guelph Ontario

Behold the humble scrap metal leftover from manufacturing at an Ontario automotive parts manufacturer.

In what one might call an auto parts odyssey, that scrap from Linamar Corp., in Guelph crosses the borders of Canada, the U.S. and Mexico seven times until it becomes an automatic transmission that powers a vehicle as much as free trade has powered manufacturing between the three nations for decades.

It’s an example not just of how much the North American automotive sector is integrated and works closely together, but how devastating U.S. President’s 25 per cent tariffs on imports from Canada and Mexico could become.

“One likely outcome in the short-term is that automakers would stop production. They would stop building,” said Kevin Hallahan, vice-president with Guelph-based Linamar, a global automotive supplier.

Canada faces 25 per cent tariffs on Canadian-made goods sold into the U.S. and Canada has pledged counter-tariffs that will be charged on U.S. goods sold into Canada.

The bottom line is the price of those products will rise dramatically and no industry can withstand a price increase of that magnitude. If it happens, automotive plants will shut down, meaning thousands of workers will be off the job on both sides of the border.

The Ontario government has put job losses from a tariff war as high as 500,000.

It would take about two years for an automaker to source new suppliers to avoid tariffs, so that will not happen any time soon.

“We could see temporary production disruptions and shut down until there’s a more coherent path forward,” Hallahan said.

Tariffs would increase the cost of a vehicle by thousands of dollars. With vehicle inventory – unsold cars – on U.S. dealer lots now totaling about three million, there is little point in keeping plants running.

As for how tariffs work, they’re paid by the U.S. importer, which is often the U.S. customer who pays the duty to the U.S. government. Ultimately the additional cost would have to be paid by car buyers. In a sector that has a seven to nine per cent profit margin, manufacturers cannot absorb a 25 per cent cost increase.

“There’s a lot of uncertainty but we’re staying calm. We will not overreact,” Hallahan said.

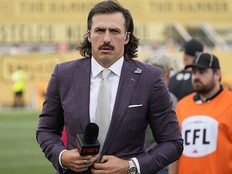

Flavio Volpe, chief executive of the Automotive Parts Manufacturers Association, cites the Linamar example of turning scrap metal into a transmission as an example of lean margins in the industry. “In an industry that doesn’t waste scrap metal, how can it absorb 25 per cent tariffs?”

Jim Farley is chief executive of Ford Motor Co. in the U.S. He said in February that Trump’s tariffs would “blow a hole” in the U.S. auto industry. Linda Hasenfratz, Linamar chief executive, added tariffs would bring the industry “to its knees” in North America.

Said Volpe: “Tariffs will shut the industry down. The best analogy I can think of is the Cold War, and the nuclear deterrence that assured mutual destruction. We didn’t end each other’s existence. The cost is just too high.”

The tariff will be levied every time that part crosses the border, as part of a larger component, meaning the 25 per cent is multiplied. Volpe likes to think of the auto industry as one large land mass built around the U.S. and Canada that includes Ontario, Quebec, Michigan, Ohio, Pennsylvania and New York state.

The North American auto pact, dating back to 1965, ensured that some vehicle production would occur in Canada. That gave way to a free trade agreement in 1988 and the Canada U.S. and Mexico Agreement (CUSMA) in 2020, signed by Trump.

“No one cared if an auto part crossed the borders six or seven times. That is, not until we have a crisis like this,” Volpe said. “We operate in an area that looks like Germany or Japan but it’s overlaid over two countries. We have highly integrated post-industrial powers that have grown together.”

At Starlim Sterner, a silicone parts maker on Tartan Drive in London, chief executive Vijay Lakshmikanthan sees his parts go back and forth across borders about four times, he said.

He gets silicone in 200-kilogram barrels from the U.S. or Germany and creates various small parts for the health care and automotive sectors. One of the automotive products he makes are seals used to keep water and debris out of plastic housings that enclose electrical systems in cars.

After receiving the silicone, he manufactures the seal and sends the parts to several automotive suppliers in the U.S and Mexico. Those seals are then installed in systems that may make their way back to Canada to be added to vehicles before returning to the U.S. where the vehicle hits dealers’ lots.

“Every domestic manufacturer in North America uses our parts. They go into all kinds of vehicles,” he said. “A lot of the assembly work is done in the U.S. and Mexico. It crosses the border anywhere from two to four times.”

The average car has more than 200 such seals in it, he added.

“It’s not good for our business. We pride ourselves on a stable flow of goods across the border. It’s an unnecessary increase in costs that will pass down at the end of the chain. It’s an enormous cost,” he said of tariffs.

At Attica Manufacturing on Invicta Court in London, owner Andy Mavrekfalos exports about 30 per cent of the parts he machines to U.S. manufacturers for everything from automotive to health care to aerospace, defence and transportation.

He now buys steel and aluminum from the U.S. and can buy from Canada or Europe, India or China but many U.S. customers demand U.S. raw material be used.

Attica employs 82 at his London plant. Complicating matters is that he also has a small plant in Port Huron, Michigan, employing five people doing work that demands a U.S.-based business, such as for the defence sector.

Shifting more production there would require a massive, costly investment of buying new technology or shipping London machinery to Michigan.

“It will eliminate our profit,” he said of tariffs. “It’s not easy to navigate and we need a deal that’s workable. We can’t absorb 25 per cent. This is a game changer.”

Volpe agrees with Hallahan that it’s not uncommon to see parts move across the border multiple times in the manufacturing process. He knows that aluminum mined in Quebec is shipped to Mexico where parts such as crankshafts and engine heads are cast.

From there parts are sent to Indiana for finishing work and the final machining is then done at a Canadian supplier in Ontario.

In one scenario, those parts will go to a GM engine plant in Tonawanda, New York, and then sent to Oshawa for assembly into a Silverado pickup truck before returning to the U.S. for sale.

Said Volpe: “I’m hoping that everyone will look at each other and say: ‘Are we really going to tank our own industry?’”

AUTO TARIFFS AND TRADE

- $1.6 trillion of goods moved between Canada, the U.S. and Mexico last year, 30% increase from 2018.

- North America produced about 16 million cars in 2023 and most are assembled using steel, equipment and parts from all three countries.

(Source: Wall Street Journal)

U.S. IMPORTS OF AUTO PARTS

- 40.4% from Mexico

- 10.3% from Canada

- 9.2% China

- 7.9% Japan

- 6.7% South Korea

- 5.7% Germany

- 19.6% Other

(Source: Wall Street Journal)

U.S. EXPORTS OF AUTO PARTS BY REGION

- 39.5% to Mexico

- 33.8% to Canada

- 2.8% China

- 2.7% Germany

- 2.1% Australia

- 19% Others

(Source: Wall Street Journal)

Postmedia is committed to maintaining a lively but civil forum for discussion. Please keep comments relevant and respectful. Comments may take up to an hour to appear on the site. You will receive an email if there is a reply to your comment, an update to a thread you follow or if a user you follow comments. Visit our Community Guidelines for more information.